AEC

Although laser scanning is more commonly associated with large construction projects it can also be used effectively on smaller projects, especially when those projects involve complicated designs. Here we provide an example of its use by Timmerhus Inc. during the construction of a custom timber-frame home in the mountains of Colorado.

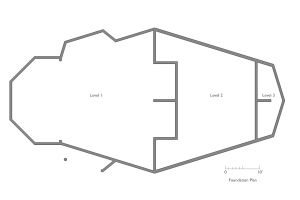

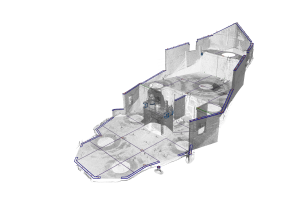

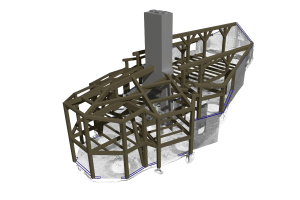

The design and construction of this building presented Timmerhus with several challenges. Their design called for the timber-frame structure to sit on top of a complex three level foundation with few right angles and parallel lines. In addition, work at the site was limited to a short window each summer when conditions allowed access. To meet these challenges Timmerhus planned to mill the timbers off-site using a CNC machine driven by their CAD design of the structure. Although this approach had many advantages it did require that the geometry of the foundation be known with a high degree of certainty.

Knowing the foundation poured the previous season was unlikely to conform exactly to the design drawings it was clear it would need to be remeasured before the timber-frame design could be finalized. Given the complexity of the foundation, Timmerhus determined that the accuracy they required would be to time consuming to achieve with traditional methods and they turned to laser scanning.

Scanning of the site was completed in a couple of hours and provided a complete point cloud model of the as-built foundation. Comparison of this model to the original plans showed that, as expected, they differed by up to several inches in some places. The point cloud was then used as reference to digitize the locations of all features relevant to the timber-frame construction including: the tops of all foundation walls, beam pockets, steal plates for setting posts, and anchor bolts. The timber-frame design was then adjusted to match these features and sent to the CNC shop. Finally, locations were measured for landmarks such as plumbing penetrations and ledgers that could be used by the framing crew to establish their on-site construction grid. Ultimately Timmerhus was able to meet their schedule and erect the back half of the structure before weather shutdown work for the season.